BLC Series - Creating Value for users Advanced technology: Based on the group's leading technology, Bolet has launched the BLC series of centrifugal compressors, committed to providing customers with advanced, efficient and energy-saving compressed air solutions。

BLC Series - Create value for users

Advanced, efficient and durable standard models

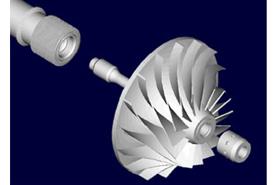

Ensure balanced rotor·Precise balancing - Each rotating part is dynamically balanced separately, and then the whole dynamic balance is done after assembly into a rotor to ensure smooth and reliable operation。 |

|

Advanced Elektronikon® control system products

·Advanced microcomputer monitoring system and human-computer interface; |

|

Adjustable blowdown valve designed for constant pressure control

·Provide automatic dual-mode control for variable flow conditions, effective energy saving; |

|

High performance cooler

·Abrasion-resistant, corrosion-resistant cooling tubes and tubes; |

|

High efficiency ternary flow backbend impeller

·Hard 174PH stainless steel material; |

|

Inlet regulating guide vane·The inlet regulating guide vane can be effectively regulated under partial load to produce preswirling airflow, expand the regulating range and save energy consumption。 |

|

Oil mist removal respirator

·Motor drive efficient oil mist removal, no need to consume gas; |

|

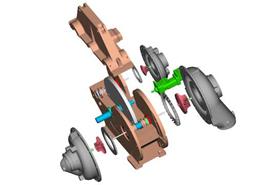

High precision gear·Meet the American Gear Association AGMA Q13/DIN5 level accuracy standard, low transmission loss, low noise, low vibration。 |

|

Easy maintenance

·High quality bearings; |

|

Super seal

·Carbon ring type gas seal and labyrinth type oil seal, reliable, long life; |

|

Stainless steel disc coupling

·Flexible stainless steel disc, high reliability; |

|

Unique micro-spline connections

·Compact design, easy to disassemble; |

|

Highly maintainable gear box

·Horizontal split gearbox and bearings for easy maintenance of gears and low/high speed bearings; |

|

Maintenance-saving intercooler

·Straight pipe design, water pipeline, gas shell process, cleaning cooler is very convenient; |

|

BLC Series centrifuge pressure/flow range |

|